Automatic moulding and filling of boluses into plastic tubes

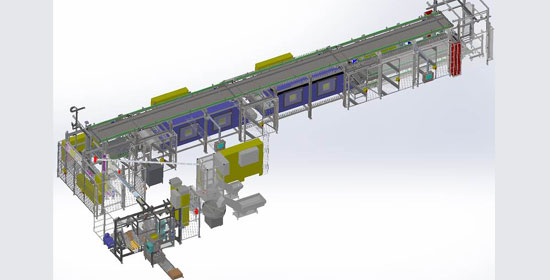

VARO has developed an integrated line for fully automatic moulding and filling of mineral boluses used in the veterinary industry. The line also includes a fully automated packaging process.

Automatic moulding, filling and packaging of boluses for dairy cows

In the line, the mineral mixture is automatically moulded and filled into plastic tubes, then closed and packed. The line includes drying and apllying of wax coating, making the bolus easier to ingest. Empty tubes are transported to filling, where the bolus is separated from the holder and placed directly into a plastic tube. Following the lid placement, the closed tubes are packed by robots into cardboard boxes, ready for shipment.

The functionalities can be adapted and mixed to meet your specific requirements. The solution has been developed for moulding and filling of boluses for dairy cows and packing them into plastic tubes, but can also be adapted for other types of products and containers.

Watch our video here or on the right hand side.

No matter the type of tube and packaging, VARO offers a complete, integrated and fully automated production line. This means, that just a single employee can control the entire line from moulding to filling and palletizing.

A filling line may include:

- Moulding of mineral mixture

- Filling of tubes

- Closing of tubes

- Packaging of tubes

Watch our video of how our highly specialised production line for calcium boluses works.

Boehringer Ingelheim produces Bovikalc, a market leading oral calcuim supplement bolus for dairy cows, on a VARO production line with fully automatic moulding of calcium boluses.

The calcium mixture is filled into bolus shaped moulds.

Bolus tubes are automatically transported to filling.

Tube lids are prepared for closing.

Closed tubes are packed by robots in a fully automated packaging process.

VAROs production line for calcium boluses automatically produces bolus shaped moulds and packs them in an automated packaging process.